Precision scanning, reverse engineering, and production-grade prints.

Quality3Ds is a premium, technical studio built for engineers, creators, and teams who need parts that fit, function, and last. From first prototype to final build, every project is driven by data, material science, and real-world use cases.

3D scanning + reverse engineering

Capture legacy parts, one-off replacements, and redesigns.

Prototype-to-production workflows

Validated materials, fit checks, and iteration support.

Material selection for durability

Application-driven choices for strength, heat, and impact.

Services tuned for innovators

Whether you are building a consumer product, medical device, or industrial fixture, our workflow adapts to your timeline and tolerances.

FDM 3D Printing

Functional parts, prototypes, and production-ready prints.

3D Scanning

Accurate scans for parts, assemblies, and legacy components.

Reverse Engineering

Turn physical parts into editable CAD for redesign or repair.

Post-Processing

Sanding, painting, polishing, and assembly-ready finishing.

Why teams choose Quality3Ds

We focus on accuracy, repeatability, and real-world performance for every part we deliver.

- 3D scanning and reverse engineering for legacy parts, one-off replacements, and redesigns.

- Prototype-to-production workflows with validated materials, fit checks, and iteration support.

- Application-driven material selection for strength, heat, impact, and real-world durability.

- Daily 3D printing pulse and research-backed guidance to keep projects future-ready.

Now shipping: multi-material assemblies

Combine rigid and flexible components in a single build to accelerate product validation and reduce assembly time.

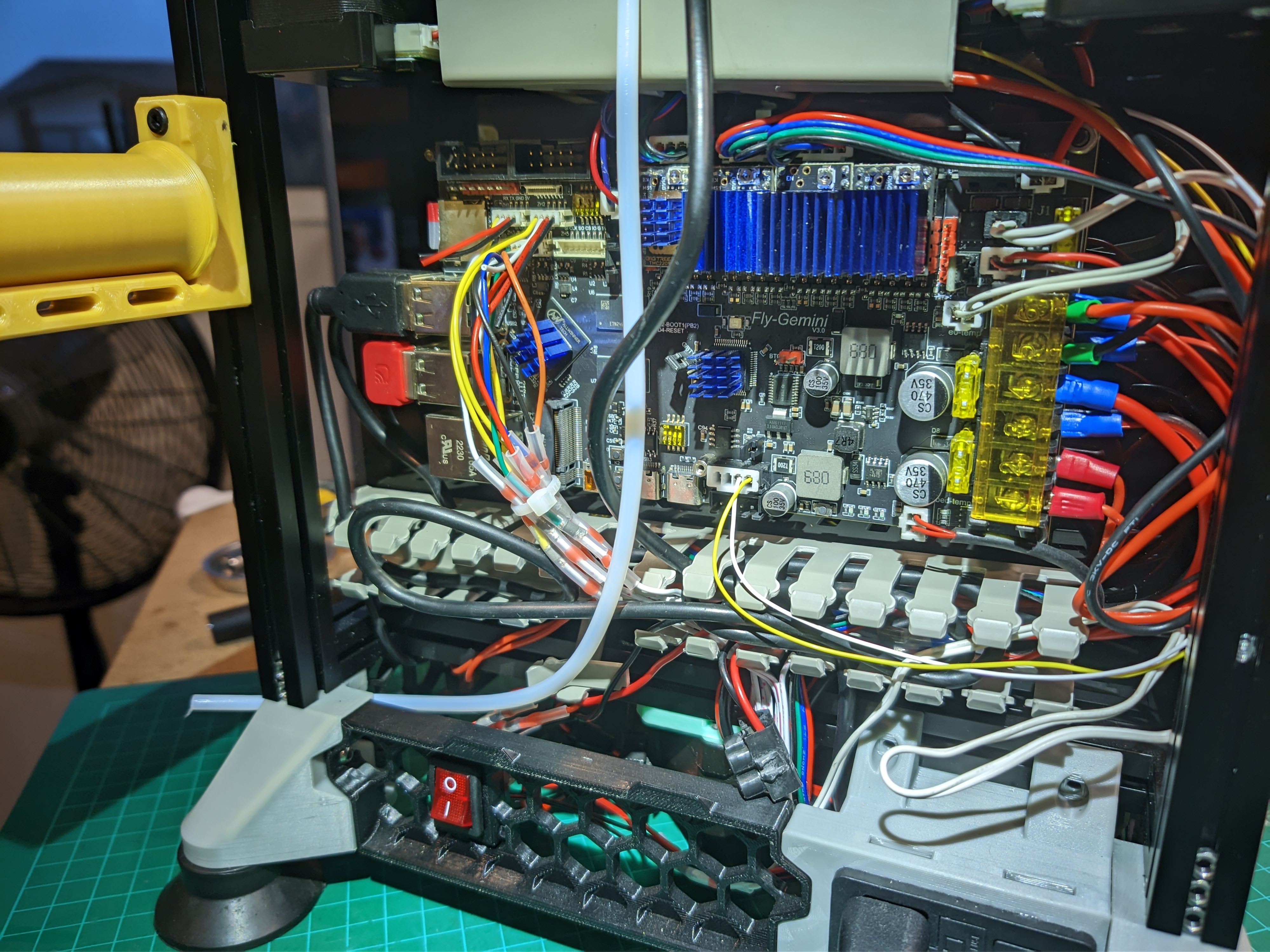

Gallery preview

A glimpse of recent builds and experimental prototypes.

3D Printing News Pulse

Curated industry insights, new materials, and hardware trends that matter to our clients.

Need production-grade parts?

Send us your design and we will provide a rapid feasibility assessment within 24 hours.